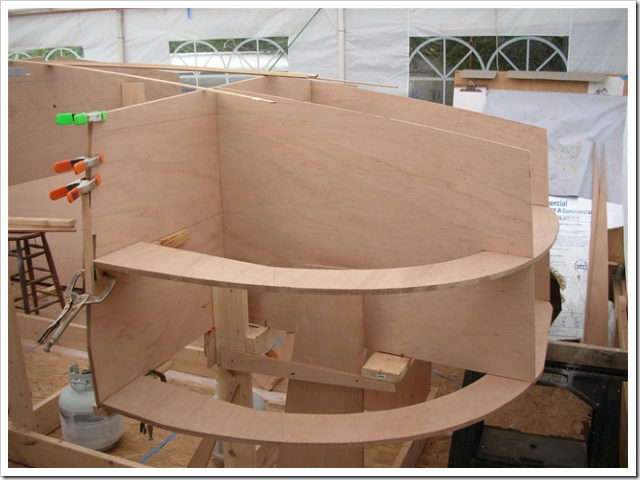

This weekend I started working on the stern. One of the most unique features of this boat is the round stern. This picture shows the two vertical pieces and the 2 hemispherical horizontal ones. The horizontal parts are not finished – I’m in the process of laminating them three layers thick each, or 2 1/4 inches thick. They will be the main structural components of the stern, with just 1/2 or 3/4 inches of hull wrapped around them.

Once this step is done I’ll be ready to put up the two forward buklheads and put the skin on the boat. Then comes the scary part of wrapping the layers of 1/4 inch plywood around the stern, keeping the whole thing fair. I might be able to put on the bottom panels next weekend.

Yesterday I spent a few hours making the bulkheads perfectly square, vertical, and in the correct alignment with each other. I used the laser level for most of this and it worked well. When I was done I set the level up forward of bulkhead three, with the vertical and horizontal lines shining through the holes I drilled at the intersection of the waterline and centerline. I held up a block behind the hole of station five, and saw a perfect cross of the lines on the block. I think all three bulkheads are aligned within a 32nd in both dimensions.

After the epoxy cured I found that I could get a fair curve by sanding with the belt sander held alternately 90 degrees and in-line with the plywood. I’ll bevel the outside of the forms after the skin panels are on, when I can fit the angle by hoding a board up to the form and the hull to see the correct angle.