I’ve been asked by a number of people how I hung the doors. There’s no standard way to do this, and I spent a lot of time trying to figure this detail out. I initially hung them from ball-bearing cars and track made for small racing sailboats, but they slid too easily and I was concerned that they would be out of control in bad weather. I couldn’t figure out a method to reliably dampen the movement. When I first tried the method below, they were too hard to open – the sliders stuck. I was ready to give up on the idea, but when I greased the sliders a little, they worked perfectly – not too easy, and not too hard to open.

Top Sliders

This method is really simple, and way more low-tech than all the other ideas I had, but the doors work really well so far.

7/8 inch sail track and nylon sail slugs:

Drill and countersink a slightly oversized hole with a 7/32 drill bit (the countersink goes on the other side):

Screw to the top of the door with a little gap. I used 3 inch stainless deck screws. The slider was loose after being attached – that is, it was free to twist and move a little. I hoped this movement would let it ‘float’ a bit in the track if things were a little out of square. I could adjust the height of the doors just by turning the screw.

Bottom Track

Hanging the doors is half of the battle – they can’t be allowed to swing out on the bottom. The doors have a 3/4 wide x 1 1/2 inch deep slot along the bottom, created by running the 1/4 inch outer plywood laminations longer than the core piece (door construction details below).

I made these bottom tracks out of 1/2 inch plastic ‘King Starboard’ because it’s slippery and weatherproof. The tracks are made a bit short to allow water to run out the ends. They’re just screwed onto the side of the pilothouse at about the right height.

The doors hang over the track.

Locking the doors

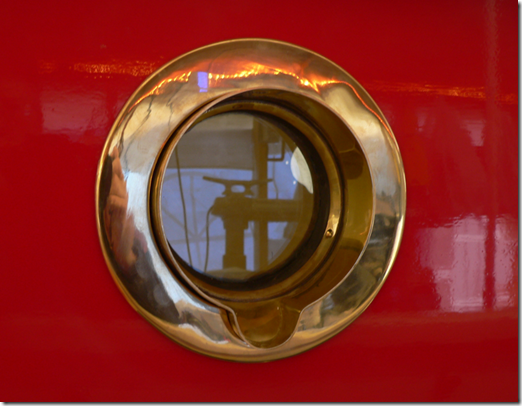

The Port door is the main entry door. It locks with a padlock through a bronze hasp. I made the hasp from 1/8 inch plate, mortised into the door before glassing. It goes through a slot in the door cowling. It’s not real elegant, but it is bulletproof. I made sure this door could slide back an extra three inches so the hasp didn’t protrude into the opening where people would be sure to run into it.

The Starboard door locks with this slide bolt. You need to latch it from the inside. The bolt has an anti-rattle slider. The second hole shown lets you open the door a few inches for ventilation, but still be secure.

Making the Doors

I made the doors from the original pieces I cut out when I made the pilothouse. First, I drew all the windows and doors on the framed-in pilothouse, then cut out the windows. Then I cut out the doors. In this picture, all the widows are cut, and the Port door is cut out. I saved the doors flat so they wouldn’t warp.

I don’t have many pictures of making the doors, but basically, I made the 1/4 inch outer skins 1 1/2 inches larger than the cutouts in all dimensions and added 1 x 2 strips to the edges and top of the 3/4 inch core before gluing the layers together. This made the doors 3 inches wider than the cutout and three inches higher. Not adding a bottom 1 x 2 created the slot at the bottom for the bottom track described above.

I made the 1/4 plywood window cutouts oversized so the windows would be attached to the 3/4 inch part as they were designed. This also made the inside of the window inset by 1/4 inch so it would have enough room to slide past the fixed window.