We flipped her over yesterday. With the great help of two friends – Jim and Eric, we got the task done in just a few hours. Not even any injuries!

There were some challenges – mostly that the tent it’s in is only three feet wider than the boat and only 18 inches higher than the beam of the boat. And the tent frame is too fragile to fasten anything to for lifting. So what we did was to spin it more-or-less in place, using ropes and come-alongs.

Here’s a sequence showing the whole process.

(Link to full-size images, hosted on Microsoft SkyDrive.)

Saturday morning I raised the stern with a hydraulic jack, set it on sawhorses, and dismantled the strongback. The bow is resting on the stem piece.

Then I swept and vacuumed below. I built a sled from a sheet of plywood with steel eyes to hook 2 come-alongs to.

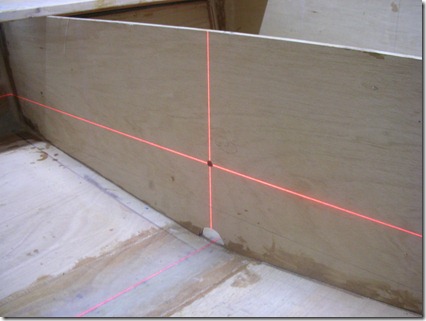

Then I slowly lowered the stern to the deck. I jacked up one side of the boat so most of the weight was on the sled. Meanwhile, I ran four lines (2 on each side) from the internal bracing around the boat and through holes punched in the tent walls to solid points on either side. The South side mounted to the house, and the North side went to a canoe rack I’d installed a couple of years ago. I replaced one of the South lines with a webbing-style come-along because I knew that would be the line that needed most of the lifting force. You can see the lines below.

Early Sunday afternoon the guys showed up and we jacked the North side up bit by bit until all the weight was on the sled. We took up the slack on the South side lines and removed the supports and the boat stayed up like we hoped it would.

More lifting. You can see the temporary diagonal braces bolted to the bulkheads. At this point we couldn’t raise any more because the side of the boat hit the tent poles on the South side. So we slid the bottom corner of the boat North using the come-alongs hooked to the sled.

More sliding. We’re approaching the point where she will want to fall to the left instead of the right, so we tightened up the North side lines.

I’m testing the line as the others stand wisely out of the way in case she slides or falls.

Adjusting the blocks on the sled. She was pretty stable in this position with all four lines tight. As far as I could tell she didn’t flex at all while we did the turning.

A little further…

Once she was fairly stable on her side we moved her over on the sled by rocking her forward and aft until she was in the right spot.

Jim and Eric lowered her down by letting out the lines a little, one at a time. Each line went through a pulley to a cleat, so they had pretty good control all the time.

Moving the sled over to keep her centered in the tent.

Almost down! You can see Jim on the right letting the line out while Eric and I steady.

She’s upright! I’ve never had such a complicated series of tasks work so well, with few unforeseen problems. A lot of that is due to the thought and safety-consciousness of the guys helping.

After flipping, we had a great meal made by Meryll, drank lots of beer, and sat around for a while. Jim had to leave, so Eric and I spent a while leveling her with jack stands and various blocks. Then we drank some more beer!